On the job

The GEMINI Powered by SAC milking robot optimises milking productivity

Organic dairy farmer Lars Remme Larsen has been using the durable, user-friendly Gemini Powered by SAC milking robot for three months. “No other commercially available robot can match the robot’s innovative design,” says Torben Pedersen, Service Manager at SAC Center Vest (Denmark), the suppliers of the robot.

Gemini Powered by SAC is responsible for milking approximately 50 of the organic farmer’s herd of 215 cows. “It can milk up to 60 cows,” says Larsen.

The milking robot is quick and easy to install. Only minor changes are needed in the barn, so there’s no need to create a separate robot room. The robot is easily accessible, easy to operate and understand, and quickly pays back the investment.

Farm worker Alex Rudenko is the usual operator of the milking robot. He says that the robot is very simple and easy to use.

Milking between the rear legs

“The Gemini milks a cow well and thoroughly, after which she can quickly resume her normal routine,” says Torben Pedersen, Service Manager at SAC Center Vest. Torben delivered and installed, with complete confidence, the milking robot at Larsen. With good reason, too, as the new robot milks differently to other robots on the market.

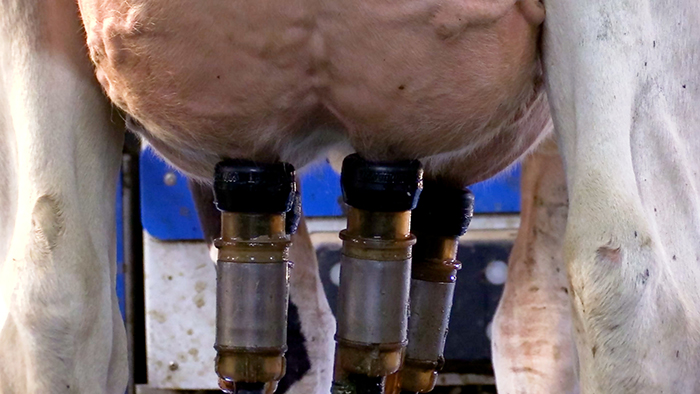

80% of all cows on dairy farms are milked from the rear. Gemini Powered by SAC is the only milking robot that operates in the same way. This keeps cows comfortable and relaxed, without being distracted by a moving robotic arm. Cows are also unable to kick people or machine components.

“As we farm organically, I've never really been interested in using robots before. Allowing the cows to graze requires close monitoring, which is a challenge when using robots. That said, it works well at lots of other dairy farms,” says Remme Larsen, who has every reason to be delighted with the new milking robot."

Enthusiastic response on the farm

Alex Rudenko, the farm worker who usually operates the robot, is also enthusiastic.

“I think the robot is a fantastic innovation. Besides milking cows, it’s a big bonus for animal health and welfare. They can’t see the robot arm, which means they really relax when they’re milked. We can now also monitor every aspect of a cow’s health in real time, so we can focus better on any problems and resolve them quickly and efficiently. The robot is very simple to operate, it increases yields, and it saves money,” says Rudenko.

SAC Center Vest delivered and installed the milking robot at Larsen’s farm. “The Gemini milks effectively,” says Torbern Pedersen, Service Manager at SAC Center Vest.

SAC unbeaten on capacity

To be honest, Lars Remme Larsen wasn’t expecting to be able to combine life as an organic dairy farmer with a fully automated milking robot.

He has farmed more than 300 hectares organically since 2000, with his farm currently home to a herd of approximately 215 cows. He bought the farm in 1996 and built a new barn, including a 2x10 SAC herringbone milking parlour, in 2000. In 2008, they started milking three times a day.

“As we farm organically, I had never really been interested in using robots before. Allowing the cows to graze requires close monitoring, which is a challenge when using robots. That said, it works well at other dairy farms, so we’ll have to learn,” says the farmer, who only has good things to say about his experience with the robot.

Larsen is delighted with its performance. “Since we started with automated milking three months ago, there has only been one alarm, which is exceptionally low in a start-up period," says Torben Pedersen of SAC Center Vest. “It’s something we can be really proud of,” he says, as the cows line up behind him, waiting to be milked by the robot.

Lars Remme Larsen explains that it won’t be long before more robots arrive at the farm. In total, two single Gemini systems and one double milking system will be installed, so it will be possible to milk four cows at the same time.

The high capacity of the SAC systems is precisely the reason it was preferred over systems from other suppliers. “We’re really looking forward to the arrival of the latest robots,” says the farmer.

The new milking robot, Gemini Powered by SAC, has been milking approximately 50 of the organic farmer’s herd of 215 cows for the last three months.

Keep it simple

According to Service Manager Torben Pedersen, the mantra when designing the new robot was to keep it simple.

The Gemini offers all the functionalities required for efficient milking, and its simple design makes it easy to use. As well as the single box, a double box system is also available, which allows two cows to be milked simultaneously, side by side.

The robot is easy to install. Only minor changes are needed in the barn, so there’s no need to create a separate robot room.

Labour shortages

Lars Remme Larsen foresees a future in which the problem of labour shortages will only increase. Besides increasing productivity and efficiency, milking robots are helping secure a positive future for dairy farming in a changing world. “In the future, it will become increasingly difficult to find people to milk cows,” says the farmer.

“We purchased the robot as a response to labour shortages. Since making this decision, our working hours have become more flexible. The SAC 2x10 herringbone parlour is used for those cows which aren’t milked by the robot. This parlour system works well, but requires a lot more labour compared to the robot. We used to milk the cows three times a day, and this would take four hours every time.” The SAC 2x10 herringbone parlour will soon be replaced by Gemini’s.

Lars Remme Larsen says that the problem of labour shortages isn’t likely to improve in the future. Besides generally increasing productivity and efficiency, milking robots are helping secure a positive future for dairy farming in a changing world.